It would appear that I was wrong in 2020 when I suggested that artificial intelligence was near the top of its hype curve [see ‘Where is AI on the hype curve?‘ on August 12th, 2020]. In the past few months the hype has reached new levels. Initially, there were warnings about the imminent takeover of global society by artificial intelligence; however, recently the pendulum has swung back towards a more measured concern that the nature of many jobs will be changed by artificial intelligence with some jobs disappearing and others being created. I believe that the bottom-line is that while terrific advances have been made with large language models, such as ChatGPT, artificial intelligence is artificial but it is not intelligent [see ‘Inducing chatbots to write nonsense‘ on February 15th, 2023]. It cannot dream. It is not creative or inventive, largely because it is very powerful applied statistics which needs data based on what has happened or been produced already. So, if you are involved in solving mysteries (ill-defined, vague and indeterminate problems) rather than puzzles [see ‘Puzzles and mysteries‘ on November 25th, 2020] then you are unlikely to be replaced by artificial intelligence in the foreseeable future [see ‘When will you be replaced by a computer?‘ on November 20th, 2019]. Not that you should trust my predictions of the future! [see ‘Predicting the future through holistic awareness‘ on January 6th, 2021]

It would appear that I was wrong in 2020 when I suggested that artificial intelligence was near the top of its hype curve [see ‘Where is AI on the hype curve?‘ on August 12th, 2020]. In the past few months the hype has reached new levels. Initially, there were warnings about the imminent takeover of global society by artificial intelligence; however, recently the pendulum has swung back towards a more measured concern that the nature of many jobs will be changed by artificial intelligence with some jobs disappearing and others being created. I believe that the bottom-line is that while terrific advances have been made with large language models, such as ChatGPT, artificial intelligence is artificial but it is not intelligent [see ‘Inducing chatbots to write nonsense‘ on February 15th, 2023]. It cannot dream. It is not creative or inventive, largely because it is very powerful applied statistics which needs data based on what has happened or been produced already. So, if you are involved in solving mysteries (ill-defined, vague and indeterminate problems) rather than puzzles [see ‘Puzzles and mysteries‘ on November 25th, 2020] then you are unlikely to be replaced by artificial intelligence in the foreseeable future [see ‘When will you be replaced by a computer?‘ on November 20th, 2019]. Not that you should trust my predictions of the future! [see ‘Predicting the future through holistic awareness‘ on January 6th, 2021]

Tag Archives: innovation

Taking an aircraft’s temperature as a health check

The title of this post is the title of a talk that I will deliver during the Pint of Science Festival in Liverpool later this month. At last year’s festival I spoke about the very small: Revealing the invisible: real-time motion of virus particles [see ‘Fancy a pint of science‘ on April 27th, 2022]. This year I am moving up the size scale and from biomedical engineering to aerospace engineering to talk about condition monitoring in aircraft structures based on our recent research in the INSTRUCTIVE [see ‘INSTRUCTIVE final reckoning‘ on January 9th 2019] and DIMES [see ‘Our last DIMES‘ on September 22, 2021] projects. I am going describe how we have reduced the size and cost of infrared instrumentation for monitoring damage propagation in aircraft structures while at the same time increasing the resolution so that we can detect 1 mm increments in crack growth in metals and 6 mm diameter indications of damage in composite materials. If you want to learn more how we did it and fancy a pint of science, then join us in Liverpool later this month for part of the world’s largest festival of public science. This year we have a programme of engineering talks on Hope Street in Frederiks on May 22nd and in the Philharmonic Dining Rooms on May 23rd where I be the second speaker.

The title of this post is the title of a talk that I will deliver during the Pint of Science Festival in Liverpool later this month. At last year’s festival I spoke about the very small: Revealing the invisible: real-time motion of virus particles [see ‘Fancy a pint of science‘ on April 27th, 2022]. This year I am moving up the size scale and from biomedical engineering to aerospace engineering to talk about condition monitoring in aircraft structures based on our recent research in the INSTRUCTIVE [see ‘INSTRUCTIVE final reckoning‘ on January 9th 2019] and DIMES [see ‘Our last DIMES‘ on September 22, 2021] projects. I am going describe how we have reduced the size and cost of infrared instrumentation for monitoring damage propagation in aircraft structures while at the same time increasing the resolution so that we can detect 1 mm increments in crack growth in metals and 6 mm diameter indications of damage in composite materials. If you want to learn more how we did it and fancy a pint of science, then join us in Liverpool later this month for part of the world’s largest festival of public science. This year we have a programme of engineering talks on Hope Street in Frederiks on May 22nd and in the Philharmonic Dining Rooms on May 23rd where I be the second speaker.

The University of Liverpool was the coordinator of the DIMES project and the other partners were Empa, Dantec Dynamics GmbH and Strain Solutions Ltd. Strain Solutions Limited was the coordinator of the INSTRUCTIVE project in which the other participant was the University of Liverpool. Airbus was the project manager for both projects.

The DIMES and INSTRUCTIVE projects received funding from the Clean Sky 2 Joint Undertaking under the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 820951 and 6968777 respectively.

The DIMES and INSTRUCTIVE projects received funding from the Clean Sky 2 Joint Undertaking under the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 820951 and 6968777 respectively.

The opinions expressed in this blog post reflect only the author’s view and the Clean Sky 2 Joint Undertaking is not responsible for any use that may be made of the information it contains.

Structural damage assessment using infrared detectors in fusion environments

About six months ago, I described the success of my research group in detecting the early stages of the development of damage in structural components using small, cheap devices based on infrared measurements [see ‘Seeing small changes is a big achievement‘ on October 26th, 2022] after it had been reported in the Proceedings of the Royal Society. The research was motivated by the needs of the aerospace industry and largely supported via the European Union’s Horizon 2020 research and innovation programme. We are planning to extend the research to allow our technology to be used for diagnostics in future fusion power plants. Plasma facing components in these powerplants will experience significant structural and functional degradation in service due to the extreme condition in the reactor. Our aim is to develop systems based on our infrared monitoring technology that can identify and track material degradation without the need for plant shutdown thereby enabling unplanned maintenance to be undertaken at the earliest sign of component failure. We are collaborating with the UKAEA and are looking to recruit a PhD student to work on the project supported by the GREEN CDT and Eurofusion. If you are interested or know someone who might be interested then please follow this link for more information.

About six months ago, I described the success of my research group in detecting the early stages of the development of damage in structural components using small, cheap devices based on infrared measurements [see ‘Seeing small changes is a big achievement‘ on October 26th, 2022] after it had been reported in the Proceedings of the Royal Society. The research was motivated by the needs of the aerospace industry and largely supported via the European Union’s Horizon 2020 research and innovation programme. We are planning to extend the research to allow our technology to be used for diagnostics in future fusion power plants. Plasma facing components in these powerplants will experience significant structural and functional degradation in service due to the extreme condition in the reactor. Our aim is to develop systems based on our infrared monitoring technology that can identify and track material degradation without the need for plant shutdown thereby enabling unplanned maintenance to be undertaken at the earliest sign of component failure. We are collaborating with the UKAEA and are looking to recruit a PhD student to work on the project supported by the GREEN CDT and Eurofusion. If you are interested or know someone who might be interested then please follow this link for more information.

Reference:

Amjad, K., Lambert, C.A., Middleton, C.A., Greene, R.J., Patterson, E.A., 2022, A thermal emissions-based real-time monitoring system for in situ detection of cracks, Proc. R. Soc. A., 478: 20210796.

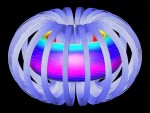

Admiral’s comments on fission hold for fusion 70 years later

Last month the US Energy Secretary, Jennifer Granholm announced a successful experiment at the Lawrence Livermore National Laboratory in which 192 lasers were used to pump 2.05 mega Joules of energy into a capsule heating its contents to 100 million degrees Centigrade causing fusion of hydrogen nuclei and the release of 3.15 mega Joules of energy. An apparent gain of 1.1 mega Joules until you take account of the 300 mega Joules consumed by the 192 lasers. The reaction in the media to this fusion energy experiment and the difficulties associated with building a practical fusion power plant, such as the Spherical Tokamak Energy Production (STEP) project in the UK (see ‘Celebrating engineering success‘ on November 11th, 2022) reminded me of a well-known memorandum penned by Admiral Rickover in 1953. Rickover was first tasked, as a Captain, to look at atomic power in May 1946 not long after first human-made self-sustaining nuclear chain reaction was initiated in Chicago Pile #1 during an experiment led by Enrico Fermi in 1942. He went on to become Admiral Rickover who directed the US Navy’s nuclear propulsion programme and the Nautilus, the first nuclear-powered submarine was launched in 1954. With thanks to a regular reader of this blog who sent me a copy of the memo and apologies to Admiral Rickover, here is his memorandum edited to apply to fusion energy:

Last month the US Energy Secretary, Jennifer Granholm announced a successful experiment at the Lawrence Livermore National Laboratory in which 192 lasers were used to pump 2.05 mega Joules of energy into a capsule heating its contents to 100 million degrees Centigrade causing fusion of hydrogen nuclei and the release of 3.15 mega Joules of energy. An apparent gain of 1.1 mega Joules until you take account of the 300 mega Joules consumed by the 192 lasers. The reaction in the media to this fusion energy experiment and the difficulties associated with building a practical fusion power plant, such as the Spherical Tokamak Energy Production (STEP) project in the UK (see ‘Celebrating engineering success‘ on November 11th, 2022) reminded me of a well-known memorandum penned by Admiral Rickover in 1953. Rickover was first tasked, as a Captain, to look at atomic power in May 1946 not long after first human-made self-sustaining nuclear chain reaction was initiated in Chicago Pile #1 during an experiment led by Enrico Fermi in 1942. He went on to become Admiral Rickover who directed the US Navy’s nuclear propulsion programme and the Nautilus, the first nuclear-powered submarine was launched in 1954. With thanks to a regular reader of this blog who sent me a copy of the memo and apologies to Admiral Rickover, here is his memorandum edited to apply to fusion energy:

Important decisions about the future of fusion energy must frequently be made by people who do not necessarily have an intimate knowledge of the technical aspects of fusion. These people are, nonetheless, interested in what a fusion power plant will do, how much it will cost, how long it will take to build and how long and how well it will operate. When they attempt to learn these things, they become aware the confusion existing in the field of fusion energy. There appears to be unresolved conflict on almost every issue that arises.

I believe that the confusion stems from a failure to distinguish between the academic and the practical. These apparent conflicts can usually be explained only when the various aspects of the issue are resolved into their academic and practical components. To aid in this resolution, it is possible to define in a general way those characteristics which distinguish one from the other.

An academic fusion reactor almost always has the following basic characteristics: (1) It is simple. (2) It is small. (3) It is cheap. (4) It is light. (5) It can be built very quickly. (6) It is very flexible in purpose . (7) The reactor is in the study phase. It is not being built now. On the other hand, a practical fusion reactor can be distinguished by the following characteristics: (1) It is being built now. (2) It is behind schedule. (3) It is requiring an immense amount of development on apparently trivial items. (4) It is very expensive. (5) It takes a long time to build because of the engineering development problems. (6) It is large. (7) It is complicated.

The tools of the academic-reactor designer are a piece of paper and a pencil with an eraser. If a mistake is made, it can always be erased and changed. If a mistake is made, it can always be erased and changed. If the practical-reactor designer errs, they wear the mistake around their neck; it cannot be erased. Everyone can see it.

The academic-reactor designer is a dilettante. They have not had to assume any real responsibility in connection with their projects. They are free to luxuriate in elegant ideas, the practical shortcomings of which can be relegated to the category of ‘mere technical details’. The practical-reactor designer must live with these same technical details. Although recalcitrant and awkward, they must be solved and cannot be put off until tomorrow. Their solutions require people, time and money.

Unfortunately for those who must make far-reaching decisions without the benefit of an intimate knowledge of fusion technology and unfortunately for the interested public, it is much easier to get the academic side of an issue than the practical side. For the large part those involved with academic fusion reactors have more inclination and time to present their ideas in reports and orally to those who will listen. Since they are innocently unaware of the real and hidden difficulties of their plans, they speak with great facility and confidence. Those involved with practical fusion reactors, humbled by their experiences, speak less and worry more.

Yet it is incumbent on those in high places to make wise decisions, and it is reasonable and important that the public be correctly informed. It is consequently incumbent on all of us to state the facts as forth-rightly as possible. Although it is probably impossible to have fusion technology ideas labelled as ‘practical’ or ‘academic’ by the authors, it is worthwhile both authors and the audience to bear in mind this distinction and to be guided thereby.

Image: The target chamber of LLNL’s National Ignition Facility, where 192 laser beams delivered more than 2 million joules of ultraviolet energy to a tiny fuel pellet to create fusion ignition on Dec. 5, 2022 from https://www.llnl.gov/news/national-ignition-facility-achieves-fusion-ignition