After five months of posting monthly, I cannot resist the temptation to slip in an extra one. Mainly because I want to let you know about the Pint of Science Festival taking place next week. In Liverpool we have organised a series of three evenings at the Philharmonic pub on Hope Street featuring talks by engineers from the School of Engineering and the Institute for Digital Engineering and Autonomous Systems (IDEAS) at the University of Liverpool. I am planning to talk about digital twins – what they are, how we can use them, what they might become and whether we are already part of a digital world. If you enjoyed reading my posts on ‘Digital twins that thrive in the real world’, ‘Dressing up your digital twin’, and ‘Are we in a simulation?’ then come and discuss digital twins with me in person. My talk is part of a programme on Digital with Everything on May 15th. On May 13th and 14th we have programmes on Engineering in Nature and Science of Vision, Colliders and Crashes, respectively. I hope you can come and join us in the real-world.

After five months of posting monthly, I cannot resist the temptation to slip in an extra one. Mainly because I want to let you know about the Pint of Science Festival taking place next week. In Liverpool we have organised a series of three evenings at the Philharmonic pub on Hope Street featuring talks by engineers from the School of Engineering and the Institute for Digital Engineering and Autonomous Systems (IDEAS) at the University of Liverpool. I am planning to talk about digital twins – what they are, how we can use them, what they might become and whether we are already part of a digital world. If you enjoyed reading my posts on ‘Digital twins that thrive in the real world’, ‘Dressing up your digital twin’, and ‘Are we in a simulation?’ then come and discuss digital twins with me in person. My talk is part of a programme on Digital with Everything on May 15th. On May 13th and 14th we have programmes on Engineering in Nature and Science of Vision, Colliders and Crashes, respectively. I hope you can come and join us in the real-world.

Tag Archives: research

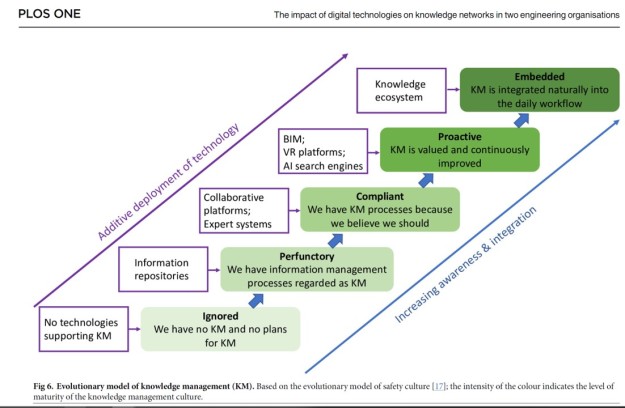

Evolutionary model of knowledge management

Towards the end of last year, I wrote about the challenges in deploying digital technologies in holistic approaches to knowledge management in order to gain organizational value and competitive advantage [see ‘Opportunities lost in knowledge management using digital technology’ on October 25th, 2023]. Almost on the last working day of 2023, we had an article published in PLOS ONE (my first in the journal) in which we explored ‘The impact of digital technologies on knowledge networks in two engineering organizations’. We used social network analysis and semi-structured interviews to investigate the culture around knowledge management, and the deployment of digital technologies in support of it, in an engineering consultancy and an electricity generator. The two organizations had different cultures and levels of deployment of digital technologies. We proposed a new evolutionary model of the culture of knowledge management based on Hudson’s evolutional model of safety culture that is widely used in industry. Our new model is illustrated in the figure from our article, starting from ‘Ignored: we have no knowledge management and no plans for knowledge management’ through to ‘Embedded: knowledge management is integrated naturally into the daily workflow’. We also proposed that social networks could be used as an indicator of the stage of evolution of knowledge management with low network density and dispersed networks representing higher stages of evolution, based on our findings for the two engineering organizations.

Hudson, P.T.W., 2001. Safety management and safety culture: the long, hard and winding road. Occupational health and safety management systems, pp.3-32, 2001

Patterson EA, Taylor RJ, Yao Y. The impact of digital technologies on knowledge networks in two engineering organisations. PLoS ONE 18(12): e0295250, 2023.

Sleeping on the job

At the end of 2023, following my visit to IBM [see ‘Chirping while calculating probabilities‘ on November 22nd, 2023], I spent a significant amount of time trying to understand quantum computing and exploring its potential applications in my research. It was really challenging because, as one article I read stated, quantum-mechanical phenomena appear to be weird and the mathematical tools used to model them are complex and abstract. Just to make it harder you have to learn a new language or at least new terminology and mathematical notation. I have always found that my unconscious mind is capable of solving mathematical problems given sufficient time and sleep. However, the mathematics of quantum computing took many nights of unconscious thought to assemble into some sort of understanding and left me with mild headaches. Around the same time I was reading one of Cormac McCarthy’s new novels, Stella Maris, which consists entirely of a psychologist interviewing a mathematician who is a patient in a hospital. They discuss that mathematical work is performed mostly in the unconscious mind and we have no notion as to how the mind goes about it. They find it hard to avoid the conclusion that the unconscious mind does not use numbers. I suspect that it does not use mathematical notation either; perhaps it is more a form of synaesthesia using three-dimensional shapes [see ‘Engineering synaesthesia‘ on September 21st, 2016]. A couple of pages before discussing the unconscious mind’s mathematical work, one of the protagonists comments that ‘If we were constructed with a continual awareness of how we worked we wouldn’t work’. So, perhaps I should not probe too deeply into how I have acquired a rudimentary understanding of quantum computing.

At the end of 2023, following my visit to IBM [see ‘Chirping while calculating probabilities‘ on November 22nd, 2023], I spent a significant amount of time trying to understand quantum computing and exploring its potential applications in my research. It was really challenging because, as one article I read stated, quantum-mechanical phenomena appear to be weird and the mathematical tools used to model them are complex and abstract. Just to make it harder you have to learn a new language or at least new terminology and mathematical notation. I have always found that my unconscious mind is capable of solving mathematical problems given sufficient time and sleep. However, the mathematics of quantum computing took many nights of unconscious thought to assemble into some sort of understanding and left me with mild headaches. Around the same time I was reading one of Cormac McCarthy’s new novels, Stella Maris, which consists entirely of a psychologist interviewing a mathematician who is a patient in a hospital. They discuss that mathematical work is performed mostly in the unconscious mind and we have no notion as to how the mind goes about it. They find it hard to avoid the conclusion that the unconscious mind does not use numbers. I suspect that it does not use mathematical notation either; perhaps it is more a form of synaesthesia using three-dimensional shapes [see ‘Engineering synaesthesia‘ on September 21st, 2016]. A couple of pages before discussing the unconscious mind’s mathematical work, one of the protagonists comments that ‘If we were constructed with a continual awareness of how we worked we wouldn’t work’. So, perhaps I should not probe too deeply into how I have acquired a rudimentary understanding of quantum computing.

BTW in case you missed my last post at the start of January [‘600th post and time for a change‘ on January 3rd 2024] and have been wondering what has happened to my weekly post – I have decided to switch to posting monthly on the first Wednesday of each month.

Source:

Cormac McCarthy, Stella Maris, Picador, 2022.

Opportunities lost in knowledge management using digital technology

Regular readers of this blog will know that I occasionally feature publications from my research group. The most recent was ‘Predicting release rates of hydrogen from stainless steel’ on September 13th, 2023 and before that ‘Label-free real-tracking of individual bacterium’ on January 25th 2023 and ‘A thermal emissions-based real-time monitoring system for in situ detection of cracks’ in ‘Seeing small changes is a big achievement’ on October 26th 2023. The subject of these publications might seem a long way apart but they are linked by my interest in trying to measure events in the real-world and use the data to develop and validate high-fidelity digital models. Recently, I have stretched my research interests still further through supervising a clutch of PhD students with a relatively new collaborator working in the social sciences. Two of the students have had their first papers published by the ASME (American Society of Mechanical Engineers) and the IEEE (Institute of Electrical and Electronics Engineers). Their papers are not directly connected but they both explore the use of published information to gain new insights on a topic. In the first one [1], we have explored the similarities and differences between safety cases for three nuclear reactors: a pair of research reactors – one fission and one fusion reactor; and a commercial fission reactor. We have developed a graphical representation of the safety features in the reactors and their relationships to the fundamental safety principles set out by the nuclear regulators. This has allowed us to gain a better understanding of the hazard profiles of fission and fusion reactors that could be used to create the safety case for a commercial fusion reactor. Fundamentally, this paper is about exploiting existing knowledge and looking at it in a new way to gain fresh insights, which we did manually rather than automating the process using digital technology. In the second paper [2], we have explored the extent to which digital technologies are being used to create, collate and curate knowledge during and beyond the life-cycle of an engineering product. We found that these processes were happening but generally not in a holistic manner. Consequently, opportunities were being lost through not deploying digital technology in knowledge management to undertake multiple roles simultaneously, e.g., acting as repositories, transactive memory systems (group-level knowledge sharing), communication spaces, boundary objects (contact points between multiple disciplines, systems or worlds) and non-human actors. There are significant challenges, as well as competitive advantages and organisational value to be gained, in deploying digital technology in holistic approaches to knowledge management. However, despite the rapid advances in machine learning and artificial intelligence [see ‘Update on position of AI on hype curve: it cannot dream’ on July 26th 2023] that will certainly accelerate and enhance knowledge management in a digital environment, a human is still required to realise the value of the knowledge and use it creatively.

Regular readers of this blog will know that I occasionally feature publications from my research group. The most recent was ‘Predicting release rates of hydrogen from stainless steel’ on September 13th, 2023 and before that ‘Label-free real-tracking of individual bacterium’ on January 25th 2023 and ‘A thermal emissions-based real-time monitoring system for in situ detection of cracks’ in ‘Seeing small changes is a big achievement’ on October 26th 2023. The subject of these publications might seem a long way apart but they are linked by my interest in trying to measure events in the real-world and use the data to develop and validate high-fidelity digital models. Recently, I have stretched my research interests still further through supervising a clutch of PhD students with a relatively new collaborator working in the social sciences. Two of the students have had their first papers published by the ASME (American Society of Mechanical Engineers) and the IEEE (Institute of Electrical and Electronics Engineers). Their papers are not directly connected but they both explore the use of published information to gain new insights on a topic. In the first one [1], we have explored the similarities and differences between safety cases for three nuclear reactors: a pair of research reactors – one fission and one fusion reactor; and a commercial fission reactor. We have developed a graphical representation of the safety features in the reactors and their relationships to the fundamental safety principles set out by the nuclear regulators. This has allowed us to gain a better understanding of the hazard profiles of fission and fusion reactors that could be used to create the safety case for a commercial fusion reactor. Fundamentally, this paper is about exploiting existing knowledge and looking at it in a new way to gain fresh insights, which we did manually rather than automating the process using digital technology. In the second paper [2], we have explored the extent to which digital technologies are being used to create, collate and curate knowledge during and beyond the life-cycle of an engineering product. We found that these processes were happening but generally not in a holistic manner. Consequently, opportunities were being lost through not deploying digital technology in knowledge management to undertake multiple roles simultaneously, e.g., acting as repositories, transactive memory systems (group-level knowledge sharing), communication spaces, boundary objects (contact points between multiple disciplines, systems or worlds) and non-human actors. There are significant challenges, as well as competitive advantages and organisational value to be gained, in deploying digital technology in holistic approaches to knowledge management. However, despite the rapid advances in machine learning and artificial intelligence [see ‘Update on position of AI on hype curve: it cannot dream’ on July 26th 2023] that will certainly accelerate and enhance knowledge management in a digital environment, a human is still required to realise the value of the knowledge and use it creatively.

References

- Nguyen, T., Patterson, E.A., Taylor, R.J., Tseng, Y.S. and Waldon, C., 2023. Comparative maps of safety features for fission and fusion reactors. Journal of Nuclear Engineering and Radiation Science, pp.1-24

- Yao, Y., Patterson, E.A. and Taylor, R.J., 2023. The Influence of Digital Technologies on Knowledge Management in Engineering: A Systematic Literature Review. IEEE Transactions on Knowledge and Data Engineering.