Perhaps my strongest memory of being taught at school is that of the head of chemistry combining hydrogen and oxygen using an old glass drinks bottle and a burning taper. The result was explosive, exciting and memorable. It certainly engaged the attention of everyone in the class. As far as I am aware, the demonstration was performed at least once per year for decades; but modern health and safety regulations would probably prevent such a demonstration today.

Perhaps my strongest memory of being taught at school is that of the head of chemistry combining hydrogen and oxygen using an old glass drinks bottle and a burning taper. The result was explosive, exciting and memorable. It certainly engaged the attention of everyone in the class. As far as I am aware, the demonstration was performed at least once per year for decades; but modern health and safety regulations would probably prevent such a demonstration today.

One of the interesting things about combining these two gases at room temperature is that the result is a liquid: water. This could be construed as an emergent property because an examination of the properties of water would not lead you to predict that it was formed from two gases. The philosopher C.D. Broad (1887-1971) coined the term ’emergent properties’ for those properties that emerge at a certain level of complexity but do not exist at lower levels.

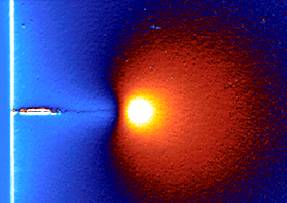

Perhaps a better example of emergent properties is the pressure and temperature of steam. We know that water molecules in a cloud of steam are whizzing around randomly,bouncing into one another and the walls of the container – this is the kinetic theory of gases. If we add energy to the steam, for instance by heating it, then the molecules will gain kinetic energy and move around more quickly. The properties of pressure and temperature emerge when we zoom out from the molecules and consider the system of the steam in a container. The temperature of the steam is a measure of the average kinetic energy of the molecules and the pressure is the average force with which the molecules hit the walls of the container.

Manuel Delanda takes these ideas further in a brilliant description of modelling a thunderstorm in his book Philosophy and Simulation: The Emergence of Synthetic Reason. There are no equations and it is written for the layman so don’t be put off by the title. He explains that emergent properties can be established by elucidating the mechanisms that produce them at one scale and then these emergent properties become the components of a phenomenon at a much larger scale. This allows engineers to construct models that take for granted the existence of emergent properties at one scale to explain behaviour at another, so for example we don’t need to model molecular movement to predict heat transfer. This is termed ‘mechanism-independence’.

Ok, that’s deep enough for one post! Except to mention that Capri & Luisi have proposed that life is an emergent property that is not present in the constituent parts of living things and which only appears when the parts are assembled. Of course, it also disappears when you disassemble a living system, i.e. dissect it.

Sources:

Chapter 1 ‘The Storm in the Computer’ in Philosophy and Simulation: The Emergence of Synthetic Reason by Manuel Delanda, published by Continuum, London, 2011 (pages 7-21).

Fritjof Capra and Luigi Luisi, The Systems View of Life: A Unifying Vision, Cambridge University Press, 2014.